Offcuts

Offcuts: Architects of the Wool Shed

In our previous blog, which focussed on the many occasions throughout history where sheep have prominently featured on Australian currency, we listed the many achievements of Ngarrindjeri man David Unaipon, who appeared on the front of the 50‑dollar note from 1995 to 2018.

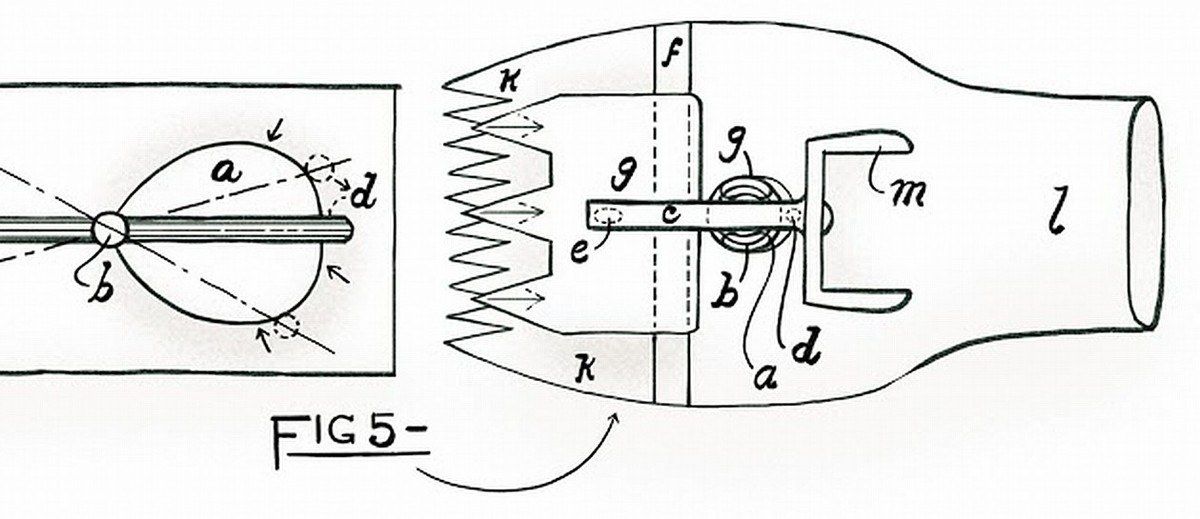

In addition to being the author of the first work published in Australia by an Aboriginal Australian, Unaipon was also a notable inventor who in 1909 developed and patented the handpiece that has since become the standard in woolsheds across the country.

Sadly, apart from a 1910 newspaper report acknowledging him as inventor, he received no credit or financial return for his groundbreaking creation and while Unaipon took out another 19 provisional patents for inventions between 1909 and 1944, he was unable to afford to get any of them fully patented.

Unaipon's plight got us

Frederick Wolseley ‑ "Wolseley's Machine"

Irish‑born inventor and woolgrower Frederick Wolseley of Euroka Station, Walgett (NSW) invented the world’s first successful shearing machine.

After years of effort, Wolseley eventually perfected his power driven mobile machine that could equal the fastest hand blade shearer and produce a better clip, closer to the animal with fewer nicks.

After a comprehensive patent was issued for the machine in June 1887, the biggest test came in the shearing season of 1888 when Dunlop station, near Bourke, “went machine”, the first property in the world to do so.

In a baptism of fire for the new invention, 184,000 sheep were successfully shorn at 40 stands, and 18 other stations were soon fitted with machines for the 1888 season.

In 1889, Wolseley sold Euroka to Dalgety Pastoral Co. and went back to the UK and formed the Wolseley Shearing Machine Co. in London.

In 1894, he resigned due to failing health and was succeeded by Herbet Austin, who later invented a motor car which he named Wolseley in honour of his former boss.

David Ferrier ‑ Ferrier Wool Press

The lever operated rack press, an Australian invention, is believed to have been designed by James Ferrier of Coleraine, Victoria, in the late‑19th century.

His patented mechanism was a huge leap forward from the previous screw‑operated press, enabling bales to be pressed in considerably less time than before.

The Ferrier wool press also won notoriety as a machine that ‘made young men old and old men think’, due to the fact that operating it was a physically demanding task

In its day, it was the most popular and innovative wool press available in Australia and was dispatched nationally by road, rail, paddle steamer and ship, as well as being exported to New Zealand, North and South America, and even Africa.

The Ferrier press was the benchmark of wool presses for many years, until hydraulics replaced the level ratchet action.

Christian Koerstz ‑ The Koerstz Wool Press

Designed by Christian Koerstz, a Danish inventor who settled in Australia in the late‑19th Century, the Koertz wool press was a cheap, efficient press for small landholders which transformed the industry.

Developed as an alternative to the large 'travelling box' presses such as the Ferrier which were too expensive for graziers of small flocks to

It occupied little floor space and could be operated by one man and by the 1930s, about 12,000 small Koerstz Selectors' and Homestead Lessees' presses had been sold around Australia and the world.

By 1910 the heavier 'Squatter' press was standard equipment in most big shearing sheds.

Dr Alastair Mackenzie ‑ Stevlyon Hydraulic Wool Press

After serving as a Naval Officer aboard HMAS Australia during World War Two, graduating from Cambridge University with a degree in Electrical Engineering and working in Weapons Research in Adelaide, Dr Alastair Mackenzie returned to rural interests in his home town of Beaufort, Victoria, in 1955.

In the early 1970’s, he began looking into wool handling practices and built a new demonstration shearing shed complete with raised and curved shearing board and revolving wool tables, as well as forming his own wool marketing business, Economic Wool Producers, in the mid 1970’s to sell wool by sample.

However it was the Stevlyon self‑pinning wool press that was perhaps Alastair's greatest achievement.

With Stevens & Lyons of Beaufort, he developed the hydraulic press which is now widely used across Australia, New Zealand, South America and elsewhere, as well as also being used in other industries where product is required to be compressed, and are considered one of the safest and most efficient presses on the market.

The Travelling Shearing Conveyor ‑ Geoff and Helen Wurst

More recently and much closer to home,

Their travelling shearing conveyor, a simple concept designed to ease the burden on backs, takes the shorn fleece straight from the shearer on their raised‑platform stand to a roustabout or classer, ready to throw on the table for classing.

Geoff and father Harry, who built the conveyor together, installed pull‑switches and a closed circuit system, run by small motors and driven through old, full circle steering boxes, so the conveyor would start when the pen door opened or via the bottom of the platform, with a lug every 1.2 metres (four feet) which either engaged or disengaged the system.

Within two weeks of being posted, the video had more than 32,000 views and had been shared over 650 times.